Quality Inspection for Pa Thermal Fusion Film For Patch - PES hot melt adhesive web film – HH

Quality Inspection for Pa Thermal Fusion Film For Patch - PES hot melt adhesive web film – HH Detail:

This is an omentum made of PES. It has a very dense mesh structure, which allows it to obtain good breathability. When combined with textile, it can take into account the bonding strength and air permeability of the product. It is often applied to some products that require relatively high air permeability, such as shoes, clothing and home textiles. Many of our customers apply this product on T-shirts and bras to meet the requirements for breathability.

The hot melt mesh film is extended by the hot melt adhesive film, and the hot-melt mesh film is formed by hot-melt adhesive melting and spinning, and can be quickly bonded after high temperature pressing. The difference between hot-melt adhesive film and hot-melt mesh film is that the hot-melt mesh film is more light and breathable and has a soft texture, while the hot-melt adhesive film is relatively airtight and has a certain thickness. From the point of view of the use effect, they are all relatively good composite products, and there are slight differences in the application fields. In some fields, the composite products do not need to have the function of breathability, so hot melt adhesive film is generally selected, and some products, such as shoes, The composite of shirts and short sleeves needs to have a certain degree of air permeability, so it is normally necessary to composite such products by hot-melt mesh.

1. Breathable: It has a porous structure which makes the mesh film more breathable.

2. Water-washing resistant:It can resist at least 15 times water-washing.

3. Non-toxic and environmental-friendly:It will not give off unpleasant smell and will not have bad influences on workers health.

4. Easy to process at machines and labor-cost saving:Auto lamination machine processing, saves labor cost.

5. Middle melting point suits most fabric.

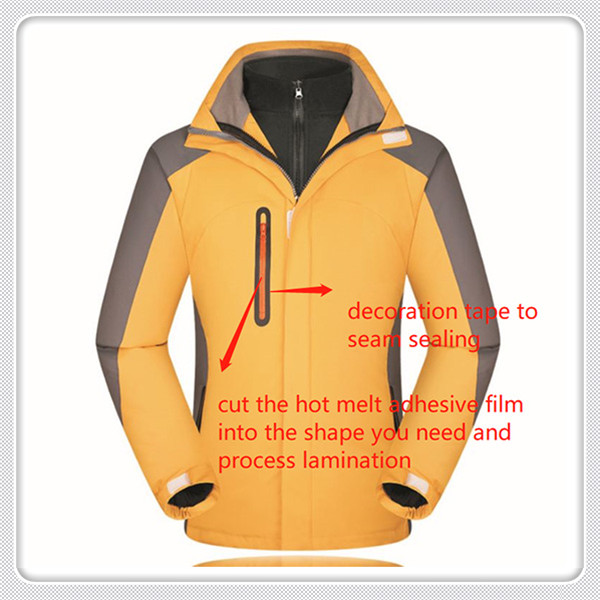

Garments lamination

PES hot melt adhesive web film has been used at garments lamination by it’s great breathablility.Since the appearance of the web film itself has many holes, it could be very breathable when used at garments to realize bonding. So many garments manufacturers all over the world prefer this kind of glue sheet.

PES hot melt mesh film can also be used at shoe materials, clothing, Automotive decoration materials, home textiles and other fields.Pes has the characteristics of resistance to yellowing, and it is precisely because of this that pes mesh is widely used in the bonding of aluminum lamps and metals, and the bonding of laminated glass crafts. In addition, pes has the characteristics of strong adhesion and washing resistance, so pes is more suitable for flocking transfer, textile lamination, embroidery badges, woven label back glue, etc.

Product detail pictures:

Related Product Guide:

H&H hot melt adhesive film: the upper lamination of leather shoes

How to choose hot melt adhesive film?

Our enterprise aims to operating faithfully, serving to all of our prospects , and working in new technology and new machine frequently for Quality Inspection for Pa Thermal Fusion Film For Patch - PES hot melt adhesive web film – HH, The product will supply to all over the world, such as: European, Borussia Dortmund, Mauritius, To have much more enterprise. ompanions, we've got updated the item list and seek for optimistic co-operation. Our web-site shows the latest and complete information and facts about our merchandise list and company. For further acknowledge, our consultant service group in Bulgaria will reply to all of the inquiries and complications immediately. They're about to make their finest effort to meet buyers need. Also we support the delivery of absolutely free samples. Business visits to our business in Bulgaria and factory are generally welcome for a win-win negotiation. Hope to expertise a happy company co-operation perform with you.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.