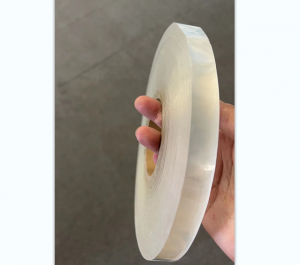

PO hot melt adhesive film for embroidery patches

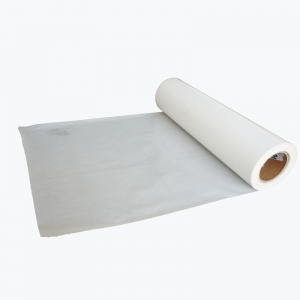

It is a PO hot melt adhesive film coated on glassine double silicon release paper. textile fabric,cotton fabric,Almunimum board,Nylon fabric compounding.

Compared with liquid glue bonding, this product behaves well on many aspects such as evironment relationship, application process and basic cost saving. Only heat-press processing, can lamination be realized.

1.good lamination strength: when applied at textile, the product will have a good bonding performance.

2.good water washing resistence: It can resist at least 20 times water-washing.

3.Non-toxic and environmental-friendly: It will not give off unpleasant smell and will not have bad influences on workers health.

4.Dry surface: It is not easy to anti-stick during transportation. Especially when inside the shipping container, due to water vapor and high temperature, the adhesive film is prone to anti-adhesion. This adhesive film solves such a problem and can make the end user get the adhesive film dry and usable.

Embroidery Patch

Hot melt adhesive film is widely used at Embroidery Patch which is popular welcomed by customers because of its easy-processing and envoronmental-friendly. Besides,Replacing traditional glue sticking,hot melt adhesive film has became the main craft that thousands of shoes material manufacturers have been applied to for many years.

L341E hot melt adhesive film can also used at aluminum panel and tube lamination.The condensing evaporator is a small part used on the refrigerator, which often involves the bonding between the aluminum tube and the aluminum plate. The bonding of this part is also widely used as a solution of hot melt adhesive film bonding. Since the aluminum tube has a circular cross-section, the actual bonding surface is just a line, and the bonding surface is small, so the bonding force of the hot melt adhesive film is still relatively high.