Subtitle: Sustainable Bonding Solutions Drive Efficiency and Durability in Modern Shoe Design

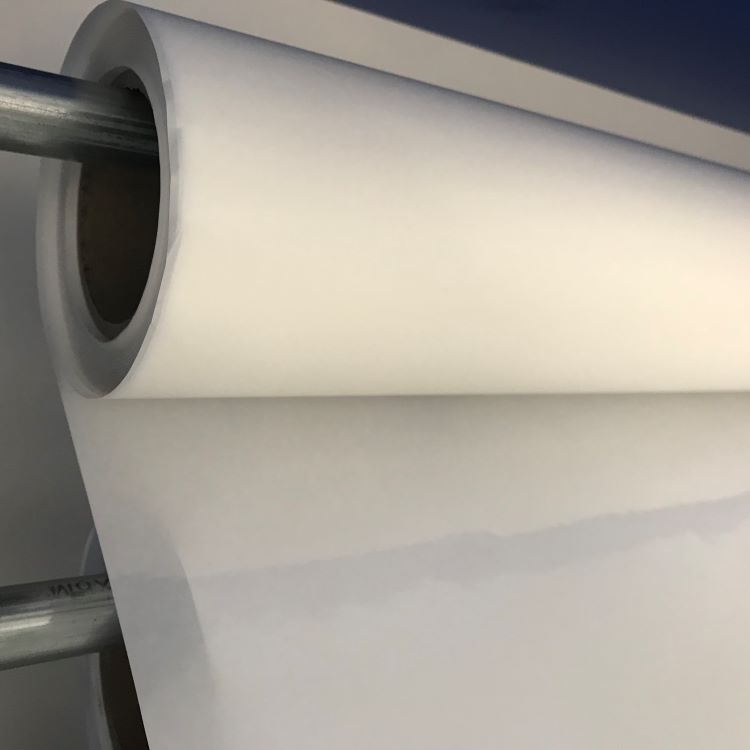

[City, Date] – The footwear industry is embracing a transformative shift as hot melt adhesives (HMAs) emerge as a game-changer in shoe manufacturing. Renowned for their precision, speed, and eco-friendly properties, these advanced adhesives are redefining how sneakers, boots, and athletic footwear are assembled, offering brands a competitive edge in performance and sustainability.

Breaking Away from Tradition

Traditional solvent-based adhesives, once a staple in footwear production, are increasingly being phased out due to environmental concerns and inefficiencies. Hot melt adhesives—thermoplastic polymers applied in molten form—provide a cleaner, faster, and more reliable alternative. Major brands like Adidas, Nike, and Timberland are adopting HMAs to meet stringent sustainability goals while enhancing product quality.

Key Advantages of HMAs in Footwear

Eco-Friendly Production

HMAs contain no volatile organic compounds (VOCs), reducing harmful emissions and aligning with global regulations such as REACH and ISO 14001. This shift supports the industry’s push toward carbon-neutral manufacturing.

Superior Bonding Performance

From rubber outsoles to textile uppers and EVA midsoles, HMAs deliver unmatched adhesion across diverse materials. Their flexibility ensures durability even under extreme conditions, critical for athletic and outdoor footwear.

Streamlined Manufacturing

With rapid curing times (seconds vs. hours for traditional glues), HMAs accelerate production cycles by up to 40%, enabling brands to respond swiftly to fast-fashion trends and custom orders.

Waste Reduction

Precision application minimizes adhesive waste, while recyclable HMA formulations support circular economy initiatives.

Industry Applications

Athletic Shoes: HMAs enhance midsole-to-upper bonding in running shoes, improving energy return and longevity.

Luxury Footwear: Delicate materials like leather and suede benefit from residue-free, invisible seams.

Safety Boots: HMAs reinforce critical joints, ensuring slip-resistant durability in industrial settings.

Pioneering Innovations

Leading adhesive manufacturers, such as Henkel, Bostik, and H.B. Fuller, are introducing next-gen HMAs tailored for footwear:

Bio-Based HMAs: Derived from renewable resources like cornstarch, these adhesives cut fossil fuel dependency.

Low-Temperature HMAs: Protect heat-sensitive materials (e.g., foams) without compromising bond strength.

Smart Adhesives: Thermally responsive HMAs enable easier disassembly for shoe recycling.

Market Growth and Sustainability

According to a 2023 report by Grand View Research, the global hot melt adhesives market is projected to reach $10.2 billion by 2030, with footwear accounting for over 25% of demand. Brands leveraging HMAs report up to 30% reductions in production costs and a 50% drop in defect rates.

“Hot melt adhesives are no longer just a bonding solution—they’re a strategic tool for achieving sustainability without sacrificing performance,” said Dr. Elena Torres, a materials scientist at Footwear Tech Institute. “The future lies in adhesives that are as intelligent as the shoes they help create.”

Looking Ahead

As consumer demand for durable, eco-conscious footwear grows, HMAs are poised to become the industry standard. Innovations in biodegradable formulations and AI-driven application systems promise to further revolutionize shoe design, making “green” footwear both accessible and high-performing.

Media Contact:

Lucas

Marketing Manager

SHANGHAI H&H HOTMELT ADHESIVES CO., LTD

Lucas@hotmelts.cn Whatsapp:+86 13677140728

Post time: Mar-11-2025