CORPORATE CULTURE

MISSION: INNOVATE FILM MATERIALS TECHNOLOGY, CONTRIBUTE TO SOCIAL PROGRESS, AND SEEK HAPPINESS FOR H&H PARTNERS

VISION: TO BECOME THE INNOVATION BENCHMARK OF THE INDUSTRY IN THE FIELD OF FILM MATERIALS AND BONDING, AND TO BECOME A RESPECTED PUBLIC ENTERPRISE

VALUES: PROFESSIONALISM, INNOVATION, CUSTOMER SUCCESS

COMPANY OVERVIEW

JIANGSU H&H NEW MATERIALS CO., LTD.WAS FOUNDED IN 2004. IT HAS TWO HIGH-TECH ENTERPRISES AND A PROVINCIAL

ENGINEERINGTECHNOLOGY CENTER. STARTED FROM HOTMELTS AND ADHESIVE FILMS, H&H GRADUALLY EXTEND TO FUNCTIONAL TAPES, TPU PPF AND TPU FILMS. WIDELY USED IN ENVIRONMENTAL PROTECTION COMPOSITE, NEW ENERGY BATTERY,ENERGY STORAGE, 3C ELECTRONICS, SHOEMATERIALS AND CLOTHING, DECORATIVE BUILDING MATERIALS AND OTHER FIELDS. OVER THE YEARS, ADHERING TO THE SPIRIT OF INNOVATION, WE HAVE MADE GREAT ACHIEVEMENTS IN ENVIRONMENTAL PROTECTIONSUBSTITUTION, IMPORT SUBSTITUTION AND EVEN INNOVATIVE APPLICATIONS. WE HAVE SERVED A LARGE NUMBER OF WELL-KNOWN DOMESTIC AND FOREIGN BRANDS AND END USERS, AND WON THE RECOGNITION AND TRUST OF INDUSTRY PIONEERS.

COMPANY LAYOUT

H&H OPERATION HEADQUARTERS AND R&D CENTER ARE LOCATED IN SHANGHAI

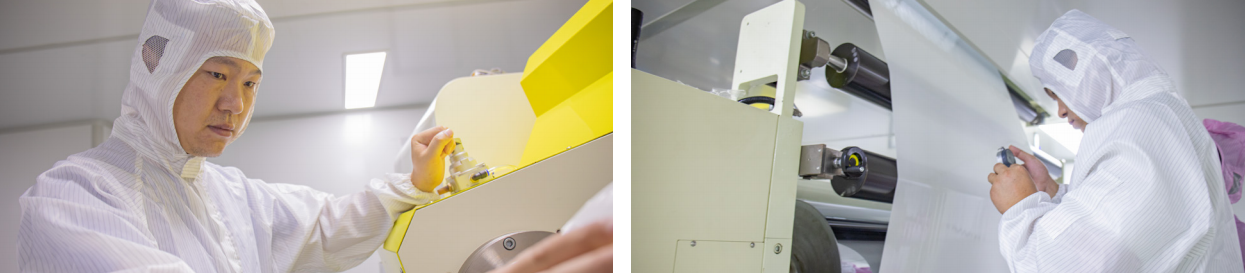

THERE ARE TWO PRODUCTION BASES IN QIDONG, JIANGSU AND GUANGDE, ANHUI, WITH VARIOUS TECHNOLOGICAL CAPABILITIES SUCH AS HOT MELT COATING, TAPE CASTING, AND PRECISION COATING.

IT HAS HUNDREDS OF MILLIONS OF SQUARE METERS OF FILM PRODUCTION CAPACITY, AS WELL AS THE PRODUCTION, DEVELOPMENT AND SUPPLY CAPABILITIES OF KEY UPSTREAM MATERIALS

H&H HAS WHOLLY-OWNED AND HOLDING SUBSIDIARIES IN WENZHOU, HANGZHOU, QUANZHOU, DONGGUAN, AND HO

CHI MINH CITY, VIETNAM, IN ORDER TO PROVIDE CUSTOMERS WITH MORE CONVENIENT SERVICES.

PRODUCTS AND APPLICATIONS

1.LITHIUM BATTERY TAPE

AIRGEL ENCAPSULATION FILM, SIDE PANEL HOT PRESSINGFILM, CCS HOT PRESSING FILM, BATTERY TAPE

2.HYDROGEN ENERGY AND ALL VANADIUM REDOX FLOW BATTERY ( VRB) FILM

LAMINATION OF POLAR PLATES AND MULTI- TYPE MEMBRANES;SEALING OF ENERGY STORAGE BATTERY STACK COMPONENTS, ETC.

3.ELECTRONIC TAPE

WAFER MASK TAPE, PLAIN LEATHER AND DECORATIVE FABRIC OF MOBILE PHONE, TABLET COMPUTER AND NOTEBOOK.BONDING OF VR AND SMART DEVICES, BONDING OF CONDUCTIVE SHIELDING MATERIALS, ETC.

4.HOTMELT ADHESIVE FILM FOR SHOES AND CLOTHING MATERIALS

UPPER SHAPING, INSOLE FITTING, FOOT PADDING,COVER HEEL, WATERPROOF PLATFORM LAMINATION, ETC.; OUTDOOR CLOTHING PACKAGING, LETTERING FILM, REFLECTIVE MATERIAL, NO TRACE BONDING OF UNDERWEAR, NON-MARKING SOCKS, CLOTHING TRADEMARKS, ETC

5.OTHER TAPE FILM

LAMINATION OF DOUBLE-SIDED TAPE AND AUTOMOTIVE INTERIOR;SEAMLESS WALL COVERING ADHESIVE FILM, SHEET COMPOSITE ADHESIVE FILM

5.OTHER TAPE FILM

LAMINATION OF DOUBLE-SIDED TAPE AND AUTOMOTIVE INTERIOR;SEAMLESS WALL COVERING ADHESIVE FILM, SHEET COMPOSITE ADHESIVE FILM

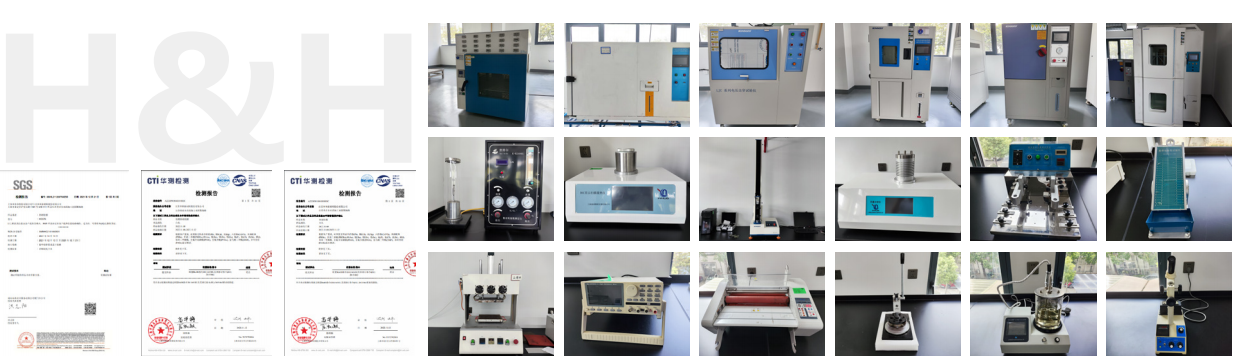

INSPECTIONCENTER

THE COMPANY HAS A PROFESSIONAL EXPERIMENTAL TESTING CENTER AND CORRESPONDING "LABORATORY MANAGE- MENT SYSTEM", WHICH CAN TEST THE PERFORMANCE, APPEARANCE, WEATHER RESISTANCE, AND OTHER ASPECTS OF PURCHASED RAW MATERIALS, SEMI-FINISHED PRODUCTS, AND FINISHED PRODUCTS TO ENSURE THAT THE PRODUCT QUALITY MEETS CUSTOMER REQUIREMENTS. REGARDING THE CONTROL OF HARMFUL SUBSTANCES IN THE COMPANY'S PRODUCTS, IN ADDITION TO CUSTOMER REQUIREMENTS, DIFFERENT SERIES OF PRODUCTS WILL BE RANDOMLY INSPECTED AND SENT FOR EXTERNAL TESTING AT A FREQUENCY OF ONCE PER YEAR TO ENSURE THAT THE CONTENT OF HARMFUL SUBSTANCES TESTED MEETS THE NATIONAL ENVIRONMENTAL PROTECTION CONTROL REQUIREMENTS.

QUALITY CONTROL

Post time: Nov-22-2024